As a seasoned lighting professional, you’re constantly on the lookout for solutions that not only enhance the aesthetics of your installations but also prioritize safety and functionality. It’s a complex job, requiring a keen eye for detail and a deep understanding of evolving technical standards and safety requirements.

Traditional downlights have been a mainstay in installations for their sleek design and solid functionality; however, underneath their polished appearance lies a significant flaw: a compromise in fire safety.

These fixtures are prone to rapid heating, posing risks to insulation and nearby flammable materials. More importantly, their installation techniques can jeopardize ceiling integrity, creating pathways for fire to spread unintendedly.

This is where the innovation of fire rated recessed lights comes into play. These advanced lighting fixtures are engineered with dual purpose: prioritize safety by enhancing fire protection while ensuring brilliant illumination through maximized lumen output. This not only guarantees a safer environment but also allows for significant cost savings with fewer fixtures.

In this guide, you will find comprehensive insight into fire rated down lights, helping you make informed decisions that resonate with the demanding nature of today’s lighting industry.

Understanding Fire Rated Down Lights

In the context of lighting, the term ‘fire rated’ signifies a specific safety feature—a guarantee that even after installation of the lighting fixture, the ceiling retains its fire-resistant capabilities.

What is a Fire Rated Down Light?

At its core, a fire rated down light is a meticulously engineered lighting fixture designed and tested to uphold the fire-resistant qualities of the ceiling or wall in which it is installed. It excels in three critical aspects: loadbearing, integrity, and insulation. This fixture ensures the ceiling or wall withstands specified loads during a fire, resists fire penetration, and prevents excessive heat transfer to the floor above.

In simple terms…

When you install traditional recessed lights by cutting a hole in the ceiling, you compromise the ceiling’s ability to resist fire. This hole can act as a pathway for fire to escape and spread more easily between different floors in a building.

Fire rated downlights are critical for fire safety as they effectively seal the hole created during installation. Each downlight is equipped with an intumescent pad that expands when exposed to a specific temperature. This expansion slows down the spread of fire.

Why is Fire Rating Required?

Fire ratings are critical for ensuring that lighting fixtures like downlights maintain structural integrity and functionality during a fire, essential for occupant safety and minimizing property damage.

In Canada, the National Building Code of Canada (NBCC) mandates fire safety standards for building materials, including lighting fixtures. Compliance with these standards is vital for legal and safety reasons.

In the U.S., the International Building Code (IBC) and local fire codes provide similar mandates. Standards such as UL 263 (Standard for Fire Tests of Building Construction and Materials) and NFPA 70 (National Electrical Code) govern fire safety in electrical installations.

Why Choose a Fire Rated Downlight?

The choice of fire rated downlights is pivotal for modern building designs due to several reasons:

- Critical in High-Risk Areas: These lights are essential in emergency routes and high-density residential buildings where the risk of fire is significant.

- Resilience to High Temperatures: Designed to withstand extreme heat, fire-rated downlights help in preventing the spread of fire, thereby enhancing overall building safety.

- Tested for Reliability: These downlights undergo stringent testing procedures to meet high-quality standards, making them reliable and durable for both residential and commercial use.

Navigating the Standards for Fire Rated Lighting

The adoption of fire rated downlights is not just a best practice but a regulatory necessity, especially in North America where safety standards are stringent.

a) The American Society for Testing and Materials (ASTM) E119

- Role and Importance: ASTM E119 serves as a key standard in the U.S. and Canada. It evaluates the fire resistance of building construction materials, including lighting fixtures.

- Application in Safety Assessments: This test method measures how long materials can resist fire, helping to determine the fire rating of various construction elements. This information is vital for architects, engineers, and lighting professionals in choosing the right materials for specific building areas, especially those prone to higher fire risks.

b) Underwriters Laboratories (UL) 263

- Widespread Recognition: UL 263 is recognized across North America for its focus on fire testing of building materials, parallel to ASTM E119.

- Significance for Lighting Fixtures: Its focus on lighting materials ensures that fixtures installed in buildings meet rigorous fire safety standards, thus contributing to the overall fire resilience of structures.

c) Canadian Standards Association (CSA)

CSA sets specialized fire safety standards for electrical fixtures in Canada, addressing unique aspects of Canadian building regulations.

d) Underwriters Laboratories of Canada (ULC)

ULC standards, while similar to CSA, provide additional safety benchmarks, ensuring that lighting fixtures meet specific Canadian performance and safety requirements.

Looking into the Compliance Requirements for Safety

Ensuring the safety of fire rated downlight installations involves adhering to specific material, construction, and installation standards.

a) Material and Construction

- Choosing the Right Materials: The selection of non-combustible or high fire-resistant materials for downlights is vital. These materials ensure that the lighting fixture can withstand extreme conditions without exacerbating a fire situation.

- Impact on Safety: Using the right materials directly impacts the fixture’s ability to resist and contain fires, playing a significant role in the overall safety of a building.

b) Installation Standards

- Following Best Practices: Adhering to the Canadian Electrical Code (CEC) in Canada and the National Electrical Code (NEC) in the U.S. is essential for safe and effective installation. These codes provide detailed guidelines on the proper installation of fire rated lighting fixtures.

- Safety and Standardization: Compliance with these codes ensures that installations meet national safety standards, reducing the risk of fire-related incidents and enhancing the overall safety of electrical systems.

c) Labeling and Certification

- Clear Identification: Proper labeling of fire rated downlights, indicating fire ratings and certifications, is crucial for quick identification and verification during inspections.

- Ensuring Compliance: Labels that include certifications like ULC, CSA in Canada, and UL in the U.S. provide assurance that the downlights meet the respective national safety standards.

Identifying and Choosing the Right Fire Rated Downlight

Selecting the right fire rated downlight involves understanding fire protection levels and identifying quality and authenticity.

a) Fire Protection Levels

- Understanding Ratings: Fire ratings like 30 minutes, 1 HOUR or 2 HOUR indicate the duration a downlight can sustain fire exposure while maintaining functionality and structural integrity. Different building areas may have specific fire rating requirements based on their fire risk levels.

- Application in Building Safety: Knowledge of these ratings helps professionals select appropriate lighting solutions that align with specific building safety requirements.

b) Quality and Authenticity

- Certification Marks: Genuine fire-rated downlights should bear certification marks from ULC, CSA, or UL, indicating compliance with respective standards.

- Material Quality: Authentic fire-rated downlights typically use superior, fire-resistant materials, often resulting in a heavier fixture.

c) Determining Fire Ratings

- Testing and Certification Process: The fire rating of downlights is established through tests like ASTM E119 or UL 263. These tests evaluate the fixture’s ability to contain fire, control temperature rise, and maintain structural integrity during a fire.

- Importance in Safety Planning: Understanding these ratings and the testing process is essential for professionals, as it informs safety planning and helps in making informed choices about lighting installations in different building areas.

Installation Best Practices for Fire Rated Downlights

Installing fire rated downlights is a task that demands precision and adherence to safety standards.

This section provides a detailed overview of best practices for installation and solutions to common challenges, ensuring compliance with U.S. and Canadian standards, including UL/ETL certifications.

1. Preparing for Installation: Planning and Site Assessment

- Fire Barrier Analysis: Begin with a thorough analysis of the ceiling’s fire barrier. This involves evaluating the material composition (gypsum, concrete, etc.) and its fire-resistive rating. Understand how the downlight installation will interact with existing fire-stopping solutions, ensuring no compromise to the barrier’s integrity.

- Thermal Imaging: Employ thermal imaging technology to identify potential heat transfer issues. This step is critical in identifying potential hotspots, particularly in areas with high insulation density or constrained ventilation, to pre-emptively address any heat dissipation issues.

- Marking the Cut-out: Accurately mark the installation area, adhering to specific fire-rated ceiling layout guidelines. This precision is essential to maintain the integrity of the fire barrier and ensure the fixture’s placement aligns with safety regulations.

2. Cutting and Fitting

- Cutting the Hole: Use a hole saw appropriately sized for the downlight. This ensures a snug fit, critical for maintaining the integrity of the fire barrier. For enhanced precision, laser-guided tools can be utilized for accurate cut-outs.

- Installing Intumescent Materials: In cases where downlights do not come with pre-installed intumescent materials, manually apply intumescent pads or seals. These materials are vital for their fire-expanding properties, helping to seal off the area around the downlight and maintain the fire rating of the installation site.

3. Electrical Connections and Wiring

- Compliance with NFPA 70 (NEC) and CEC: Follow wiring methods in line with the National Electrical Code (NEC) in the U.S. and the Canadian Electrical Code (CEC). This includes using wires and junction boxes that are rated for fire resistance and suitable for the electrical load.

- Circuit Integrity: Rigorously check the circuit’s ability to function under potential fire conditions. Factors like voltage rating, circuit length, and load demand should be carefully evaluated to prevent electrical failures in fire scenarios.

4. Mounting and Fixture Installation

- Selection of Fire-Rated Mounting Hardware: Select mounting hardware specifically rated for fire safety, compatible with both the downlight model and the ceiling material. This choice is crucial in maintaining the fire-resistance level of the overall installation.

- Vibration Analysis in Dynamic Environments: In areas prone to significant vibration or movement, such as industrial settings or buildings with heavy foot traffic, conduct a detailed vibration analysis. This ensures the long-term stability and safety of the mounted fixtures.

5. Final Integration and Aesthetic Consideration

- Architectural and Design Integration: Focus on how the downlights blend aesthetically with the surrounding architecture. Consider trim design, color temperature, and beam angle, ensuring the downlights complement the overall design while providing effective illumination.

- Acoustic Impact: Evaluate the potential impact of downlight installations on the acoustic properties of the space. This is particularly crucial in environments with stringent soundproofing or acoustic requirements.

Safety Meets Savings: The 5CCT Fire Rated Thin Line

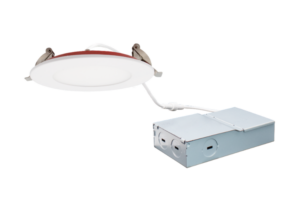

The 5CCT Fire Rated Thin Line represents a significant advancement in fire-rated lighting technology.

It’s designed to cater to various applications, both residential and commercial, in compliance with the stringent safety requirements prevalent in the U.S. and Canada.

Salient Features

- Fire Resistance Rating: The fixture is equipped with a 2-hour fire rating, which is significant in contributing to a building’s fire safety measures. This rating indicates the duration the fixture can withstand fire exposure while maintaining structural integrity and function.

- Compliance with North American Safety Standards: The product is cETLus listed, ensuring it adheres to the safety regulations set forth in both the United States and Canada. This listing is indicative of the product’s alignment with UL and ETL standards, which are crucial benchmarks in North American safety certifications. Additionally, its compliance with Energy Star guidelines underscores its energy efficiency.

- Color Temperature Range: The fixture provides a range of color temperatures, adjustable from 2700K to 5000K (5CCT). This feature allows for the tailoring of lighting ambiance to suit different environmental and aesthetic requirements.

- High Lumen Output: Despite its fire-rated design, the fixture does not compromise on brightness. The 4-inch model delivers 800 lumens, while the 6-inch variant offers 1100 lumens, ensuring ample illumination for various settings.

- Installation Features: The fixtures are designed with spring-loaded clips, enhancing compatibility with a variety of ceiling materials, including double-layered drywall. This feature simplifies the installation process and makes it more efficient.

Cost-Effectiveness and Energy Efficiency

The 5CCT Fire Rated Thin Line embodies cost-effectiveness in several aspects, crucial for both distributors/contractors and end-users:

- Energy-Saving Design: The efficient 120V connection, adaptable to 347V, positions the 5CCT line as an energy-saving solution. This attribute is particularly beneficial for reducing long-term operational costs, making it an attractive option for eco-conscious clients and those with budgetary constraints.

- Broad Market Application: The combination of safety, energy efficiency, and design versatility broadens the product’s applicability across various sectors. This adaptability makes it suitable for a wide range of projects, enhancing its marketability and potential for volume sales.

Warranty and Economic Competitiveness

- Extended Warranty: The inclusion of a 5-year limited warranty signifies the product’s durability and reliability, suggesting a reduced need for replacements and maintenance, thus contributing to cost savings over time.

- Competitive Pricing: The product is positioned at a competitive price point in comparison to similar products in the market. This pricing strategy is particularly advantageous for large-scale projects or clients with strict budget limitations, where cost is a pivotal factor alongside quality and compliance.

The 5CCT Fire Rated Thin Line stands out as a practical choice for professionals looking for a blend of safety, efficiency, and affordability in lighting solutions. Its energy-saving features, compliance with U.S. and Canadian safety standards, and competitive pricing make it an attractive option.

For contractors and architects, integrating such products into their projects means meeting client needs effectively while adhering to budget and safety requirements.